In my last post I looked at some general tips on how to see the shop floor. Most of them involve focusing on the right areas of the shop floor, and avoiding interesting but not relevant technical details. This post will discuss different aspects that can be observed. Here, too, try not to see everything at the same time. This will make you like a young tiger hunting ducks; if he tries to catch them all, he will catch none.

In my last post I looked at some general tips on how to see the shop floor. Most of them involve focusing on the right areas of the shop floor, and avoiding interesting but not relevant technical details. This post will discuss different aspects that can be observed. Here, too, try not to see everything at the same time. This will make you like a young tiger hunting ducks; if he tries to catch them all, he will catch none.

Visual Management

One way to look at a shop floor is to focus on visual management. Visual management is often misunderstood as “label and mark everything,” but labeling and marking is only part of visual management, and even then you should not label and mark “everything.” The basic idea of visual management is to have a shop floor that is quickly and easily understood merely by looking at it. For example, if your inventory is well organized, you can see with one glance which material you have enough of and what parts you need. If your inventory is a mess, then you either have to spend a lot of time counting, or look at some data, hoping that the data is actually correct.

Hence, to estimate whether the shop floor has good visual management, try to see whether you understand what is going on without much explanation. For example, follow the material flow. Do you know which inventory goes where, and which one is too much or too little? Even more important is to follow the information flow. At a process, I love to ask how they know what to do. I love to ask where the material comes from, and how they know when to deliver it. I then go to the preceding process or inventory and repeat the same questions. Of course, someone on the shop floor (usually) knows. But… is it intuitive? If you were a new employee being trained in handling the information flow, would you understand?

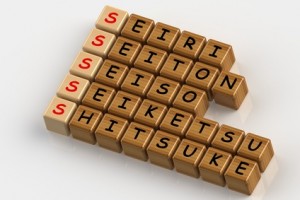

5S

In English, 5S stands for Sort—Set in Order—Shine—Standardize—Sustain, or similar words starting with S. It is based on similar words in Japanese, and is one of the basic methods in lean manufacturing, used to create and maintain a clean and organized work environment. The exact sequence is not so relevant, as there are also 4S and up to 8S methods, but the words help you to get an organized and safe workplace… and to keep it that way. Hence, I sometimes also focus on general order and cleanliness. There is also a risk that this is done too much, but it is much more likely to see too little order and cleanliness.

In English, 5S stands for Sort—Set in Order—Shine—Standardize—Sustain, or similar words starting with S. It is based on similar words in Japanese, and is one of the basic methods in lean manufacturing, used to create and maintain a clean and organized work environment. The exact sequence is not so relevant, as there are also 4S and up to 8S methods, but the words help you to get an organized and safe workplace… and to keep it that way. Hence, I sometimes also focus on general order and cleanliness. There is also a risk that this is done too much, but it is much more likely to see too little order and cleanliness.

To look for 5S on the shop floor is generally to look for order and cleanliness. Is it clean? Note that the requirement here may be different in a wafer fab than in a blacksmith workshop. In fact, all subsequent points can differ depending on the manufacturing type. Are there any spills or leaks on the shop floor? Does the shop floor appear cluttered? Does it feel organized? Do tools, materials, and other equipment have their proper place? Are they in their proper place? Is anything missing? Are the tools in working order, not broken or worn out? Is everything properly marked that has to be marked? I’m sure you can think of tons of additional questions that help you to understand the topic of 5S.

A nice example I always love to show is the comparison of these two working vehicles below. One is organized, the other is not. One has 5S, the other doesn’t. One uses visual management, the other one not.

Waste

Waste is one of the three evils in manufacturing, besides unevenness and overburden (or in Japanese, muda, mura, muri). Hence, one possible aspect to look at on a shop floor is waste. I’m sure you’re familiar with the seven types of waste (transport, movement, waiting, over processing, defects, inventory, and—worst of all—overproduction).

Waste is one of the three evils in manufacturing, besides unevenness and overburden (or in Japanese, muda, mura, muri). Hence, one possible aspect to look at on a shop floor is waste. I’m sure you’re familiar with the seven types of waste (transport, movement, waiting, over processing, defects, inventory, and—worst of all—overproduction).

I mostly observe waste qualitatively. Simply go through the seven types of waste. Can you see excessive transport? Are there unnecessary movements? When and where? How often do you see people waiting? Waiting can also be observed in machines, although there it is less significant. Overproduction may be hard to observe, but you can still look for it. Defects are also hard to see since they are hopefully rare. For this you may rather look at available data (see my subsequent posts for more).

Inventory is usually the easiest to see… but inventory is also necessary. Try to estimate whether there is too much inventory… which usually indicates too many fluctuations, or our last type of waste: overproduction. Seeing overproduction directly is difficult, and mostly observed through inventory, albeit there are also other influences that increase inventory, like fluctuations. Especially for inventory, you can also count, or estimate. How much material is there in one inventory? Combined with the consumption rate, you can estimate the inventory reach. Combining the available inventory with the total space gives you the fill level of the inventory. There is a lot of quick and easy data that you can collect yourself on inventory.

Inventory is usually the easiest to see… but inventory is also necessary. Try to estimate whether there is too much inventory… which usually indicates too many fluctuations, or our last type of waste: overproduction. Seeing overproduction directly is difficult, and mostly observed through inventory, albeit there are also other influences that increase inventory, like fluctuations. Especially for inventory, you can also count, or estimate. How much material is there in one inventory? Combined with the consumption rate, you can estimate the inventory reach. Combining the available inventory with the total space gives you the fill level of the inventory. There is a lot of quick and easy data that you can collect yourself on inventory.

I usually avoid the Western addition of the eighth type of waste—unused human creativity—maybe because I come from Toyota, and maybe because it is just so hard to see and even harder to measure.

If possible, I also try to measure the waste in manufacturing. This is especially useful for manual work like assembly. What percentage of time does the worker add value, and what percentage of time is wasted for other tasks? I do this by simply counting workers and estimating whether they are adding value when I observe them or not. For details, see my post How to Estimate Value Add for Manual Work – How to See Waste!. Defects are harder to observe directly, and you may have to rely on the available data for that.

Overall, there are many things to observe on the shop floor. In this post I looked at visual management, 5S, and waste, which are probably the easier ones. In my next post I will look at unevenness, overburden, and safety. Unevenness and overburden especially are a bit more difficult to see than waste, but there are still many things that you can observe. Finally, while the observation on the shop floor reigns supreme, some information you can only obtain through collected data. Now, go out, see your shop floor through the eyes of visual management, 5S, and waste, and organize your industry!

May I ask what your thoughts are on a visual workplace in the office environment and any advice that you could offer?

My take is that office workers ‘work’ is done in the virtual world and the emphasis should be on well ordered and easy to navigate file structure. I’ve tried to encourage use of the 31 second rule as the primary tool. That being within sec recognise the folder structure is standard, 10 sec find the file and in sec sec of opening it up be able to find the information of interest.

Hi Jonathan, that is a good point. One big challenge of understanding office work is that the work and the inventory is “hidden” as files or paper. Having a good understandable file structure definitely helps. I put a lot of effort into naming my files correctly, but could improve with my file structure I have to admit…

This is a real example about how to implement lean logistics.

https://loypro.wordpress.com/2018/06/10/dos-nuevos-conceptos-catlean-clean/

Do you want a translation? Select “inglés” in the window at the right side of the screen.

We used to consider ‘The Obvious Factory’ (or office / wherever) as the ideal. All the 5W+1H are clear, without recourse to verbal explanation. Visual management related to things; visible management related to information.

Hello Chris, great post, I learned a lot from reading this article. I was wondering if there were any challenges associated with observing and measuring the 8 types of waste on the shop floor?

Hi Kevin, the 7 (8 with unused creativity) types of waste are easier to see on the shop floor, but even then it is not always easy. Some are quite hard to measure (Especially the unused creativity).