Digital shop floor dashboards are popular nowadays, and are found in many companies. However, they often seem more like a decorative element than a functional way to transfer information. In this blog post, I will look deeper into the possibilities and problem with digital shop floor displays and how to make them work. This blog post was inspired by the Van of Nerds trip through France in 2022, organized by Franck Vermet and Michel Baudin.

Digital shop floor dashboards are popular nowadays, and are found in many companies. However, they often seem more like a decorative element than a functional way to transfer information. In this blog post, I will look deeper into the possibilities and problem with digital shop floor displays and how to make them work. This blog post was inspired by the Van of Nerds trip through France in 2022, organized by Franck Vermet and Michel Baudin.

Introduction

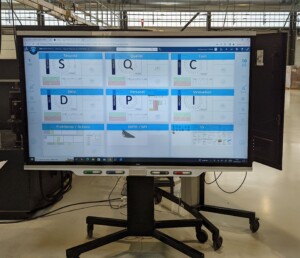

The need for regular and structured shop floor meetings is clear, and I have written a quite few posts on this before. These meetings convey vital and timely information on the current state of the operations, to the people who need it. Such meetings greatly benefit from visuals when discussing the important topics of safety, quality, time, and cost as well as ongoing improvements and changes.

The need for regular and structured shop floor meetings is clear, and I have written a quite few posts on this before. These meetings convey vital and timely information on the current state of the operations, to the people who need it. Such meetings greatly benefit from visuals when discussing the important topics of safety, quality, time, and cost as well as ongoing improvements and changes.

Many of such shop floor meetings are still conducted using pen or printouts and paper, which I am quite happy with. However, more and more companies have switched to digital. I saw my first digital shop floor boards fifteen years ago, when large LCD displays still cost a fortune. Unfortunately, while the company back then was proud of their digital displays, the workers rarely ever used it for an actual meeting.

Why Go Digital

The advantages of digital over paper is often quite clear. The also present disadvantages, however, are much less understood. As for the advantages, a digital display, or more generally a computer, can retrieve and send information from a database. Hence, you have the latest data from your servers, and data entered through the shop floor display is immediately available to everybody. Sharing data, creating backups, and archiving is much easier.

The advantages of digital over paper is often quite clear. The also present disadvantages, however, are much less understood. As for the advantages, a digital display, or more generally a computer, can retrieve and send information from a database. Hence, you have the latest data from your servers, and data entered through the shop floor display is immediately available to everybody. Sharing data, creating backups, and archiving is much easier.

As for the downsides, employees seem to be much less involved in digital displays than in what they write or document themselves. Adding data into a computer is also a bigger hurdle than by pen on a paper, especially if not all of your people are digital natives. Finally, in my experience the quality of the data in the system is often not as good as you would like it to be. It is rare to see a 100% digital-only shop floor corner without any paper. Anyway, let’s have a look at the particular challenges of digital shop floor displays.

Information Overload

The first major risk of digital displays is an information overload. The computer has access to all (or at least a lot) of the data in the system. There is the temptation of developers to add features and give access to everything there is…with the risk of overloading the employees. This applies also to paper-based shop floor boards, but the risk of “too much” is much higher for digital display boards. Be aware that you as a manager or supervisor may feel much more comfortable navigating your companies cyberspace than many of the blue collar workers.

The first major risk of digital displays is an information overload. The computer has access to all (or at least a lot) of the data in the system. There is the temptation of developers to add features and give access to everything there is…with the risk of overloading the employees. This applies also to paper-based shop floor boards, but the risk of “too much” is much higher for digital display boards. Be aware that you as a manager or supervisor may feel much more comfortable navigating your companies cyberspace than many of the blue collar workers.

I am a great fan of “less is more,” and would think carefully on what I actually need for a shop floor meeting (things like safety, quality, time, cost, and problem solving). It sometimes feels that developers see a digital display on the shop floor as just another ERP terminal with a bigger monitor and fancy graphics. Make sure you know what you want and that the system can deliver.

Usability

This information overload is closely connected to a second risk: usability. How easy is it to use the display board? How easy is it to get data? How easy is it to add data? Nowadays, a touchscreen is common. But most digital boards still need a mouse and a keyboard as backup. If you want to write something, a keyboard is really helpful. (In the future, voice recognition may work, but in terms of reliability we are not yet there).

Again, don’t assume a digital native; assume someone who rarely uses computers. This is often a point of failure. The people who develop and program digital display software are extremely good at using computers… and hence may overlook the needs of the people less fluent in binary. If you get a digital display board, make sure it is usable. Don’t just let the people who know its ins and outs show you, but try it yourself. Maybe get a person from the shop floor to tag along and to try it out. I have seen digital display boards that seemed to work, but I have also seen boards that left me puzzled.

It is by no means easy to create simple and useful summaries that should go onto the digital display board. Compounding the problem is that often the programmers have no clue about the shop floor, and the shop floor has no clue about programming. You end up with a product like dog food that is designed to appeal to the owners but not necessarily to the dogs.

Data Integration

Probably the biggest challenge is to integrate the data. This is not only a challenge for the digital display board, but for the entire ERP system. The idea in theory is that each machine sends its data to the ERP system. The problem is that different machine tool makers and even different machines from the same tool maker have different data formats and definitions. One maker may define a stop as a machine that is completely off, others see a stop as a machine that is on but not producing, which again others see as a running machine. Different definitions, different sensors, different data formats, and many other different digital things make it a god-awful mess to get the data in the same useful database. There is simply no standard for communication between different machines. If a maker advertises such a standard, more often than not it simply means that all other makers should conform to their internal standard. Sone companies end up with multiple displays, one for each tool maker.

Probably the biggest challenge is to integrate the data. This is not only a challenge for the digital display board, but for the entire ERP system. The idea in theory is that each machine sends its data to the ERP system. The problem is that different machine tool makers and even different machines from the same tool maker have different data formats and definitions. One maker may define a stop as a machine that is completely off, others see a stop as a machine that is on but not producing, which again others see as a running machine. Different definitions, different sensors, different data formats, and many other different digital things make it a god-awful mess to get the data in the same useful database. There is simply no standard for communication between different machines. If a maker advertises such a standard, more often than not it simply means that all other makers should conform to their internal standard. Sone companies end up with multiple displays, one for each tool maker.

For example, the biggest and most dominating Industry 4.0 project at Bosch right now is an attempt to get all the data on the same platform. This is a huge undertaking. Another approach I know is Keyprod, which uses a vibration sensor on the machine (more in a future blog post) to completely bypass the internal sensor and data of the machine. JPB, the maker of Keyprod, also spent a lot of effort to create an app that gives access to the shop floor data when traveling, including warehouse parts, work instructions, production plan, production performance, geometry data, and an ERP interface. They use a smaller, almost home-grown ERP system to make this happen.

Yet another example we saw is at LISI, where they put in all the effort to get the data on the same platform. They use a digital shop floor management provider Fabriq, a French startup, for their displays and a mobile app. This seems to work. What surprised me, however, was that all the data is stored not at LISI but at Fabriq.

This integration of data is often overlooked, and people are surprised later on how hard this is. And it is really difficult to do, but also necessary. Now, go out, get your data on the same platform, and organize your industry!

See also

Fellow nerd Michel Baudin has also blogged on digital displays, inspired by the Van of Nerds, including the following:

Hi,

Thank you for your very interesting post.

As I have been director of operations in many industries, I dream of this electronic board during many years. I am also a Master Black Belt and I belive the shoopfloor daily meeting is key to manage the activity and identify key improvements.

As I am a consultant since 2012, I can testimony that I have seen a real top exemple of what could be the top in this area.

This solution combine electronic board metrics for the yields , where you can dig by product, by process stepand by root cause (using BI) to a manual ( hand written) to do list for next meetin. Very impressive and it works really.

Further to my earlier post, i do think you do an excellent job of establishing the criteria for a good solution. I would be pleased to offer a demonstration of our CONNECT solution just to get your feedback on further improvements.