Continuously moving assembly lines are commonly found in industry, especially high-volume production. Most final assembly lines in automotive are continuously moving lines, but there are also many more examples in industry. Such lines have many of the same requirements of pulsed or untimed lines, but in a few specific circumstances continuously moving lines can have an advantage. This first post of this small series looks at the basic commonalities and differences between pulsed and continuously moving lines. The next posts looks at the mathematical relation between speed, work content, and line length, before a third post explores in more depth the unique issues of line balancing for continuously moving assembly lines. A final post looks at some unique features for continuously moving assembly lines.

Continuously moving assembly lines are commonly found in industry, especially high-volume production. Most final assembly lines in automotive are continuously moving lines, but there are also many more examples in industry. Such lines have many of the same requirements of pulsed or untimed lines, but in a few specific circumstances continuously moving lines can have an advantage. This first post of this small series looks at the basic commonalities and differences between pulsed and continuously moving lines. The next posts looks at the mathematical relation between speed, work content, and line length, before a third post explores in more depth the unique issues of line balancing for continuously moving assembly lines. A final post looks at some unique features for continuously moving assembly lines.

Continuously Moving Line vs. Pulsed and Untimed Line

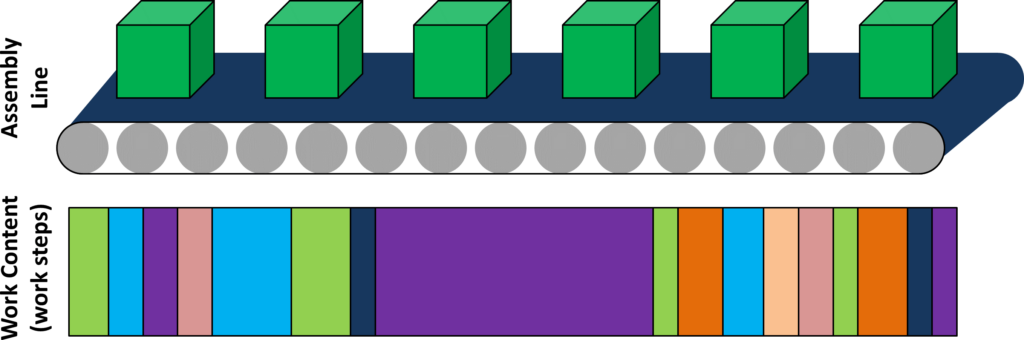

In the continuously moving line, the parts are – as the name says – continuously moving. This is usually an automatic transport system like a conveyor belt, a moving walkable platform, pulling by an underground chain, or moving hanging carriers, to name just a few. Below is a quick animation to show you the concept. I have written more on continuously moving lines in my blog post here.

This is to be contrasted with a pulsed line or even an untimed line, where there are fixed workstations. Both are shown below.

Line Balancing on Pulsed or Untimed Lines

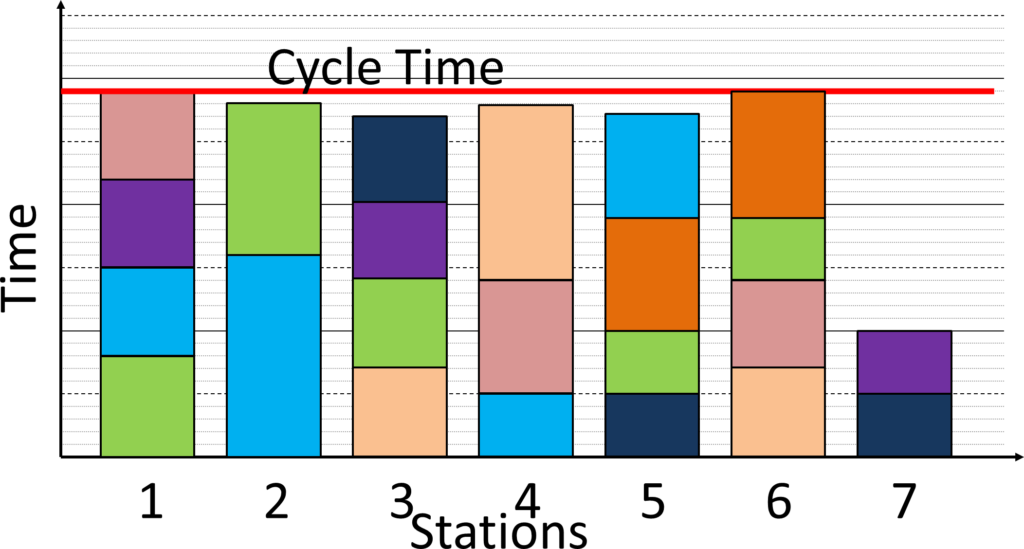

Balancing the workload among the different processes of a manufacturing system is usually straightforward. It reduces unevenness (mura) due to different workloads. This in turn will reduce wasted waiting time (muda) for those with too little work, and overburden (muri) for those with too much. I have written a whole series on line balancing starting with the post Line Balancing Part 1 – Data Overview. Basically, you try to distribute the work content within the target cycle time as well as you can.

Work Content on Continuously Moving Assembly Lines

Continuously moving assembly lines differ from unstructured or pulsed assembly lines, since the line and hence the parts are continuously moving. In a pulsed line, all parts move to the next station at every takt. Any work not done at a station within the takt requires the line to stop. If a station temporarily takes more time than the takt, the line is delayed until the station is done with its work. This is, by the way, the famous principle of the andon line, where every worker on the line can stop the line. Line balancing at normal assembly lines requires the distribution of the work content into chunks that fit the line takt (or, more precisely, the cycle time).

Continuously moving assembly lines differ from unstructured or pulsed assembly lines, since the line and hence the parts are continuously moving. In a pulsed line, all parts move to the next station at every takt. Any work not done at a station within the takt requires the line to stop. If a station temporarily takes more time than the takt, the line is delayed until the station is done with its work. This is, by the way, the famous principle of the andon line, where every worker on the line can stop the line. Line balancing at normal assembly lines requires the distribution of the work content into chunks that fit the line takt (or, more precisely, the cycle time).

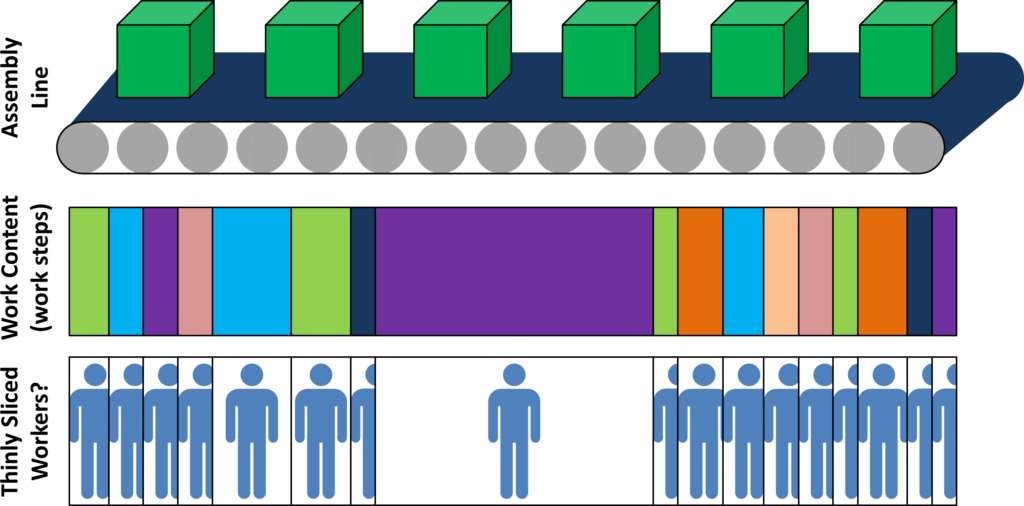

For a continuously moving assembly line, this is a bit easier (although there is still a catch and in most cases you still need to fit the work into the takt). But, in pure theory, you can simply take all the work content and distribute it along the continuously moving assembly line. A task that takes longer gets more space, and a task that is shorter gets less. You can imagine this like taking all your work steps and stacking them on top of each other. Then you simply lay this stack of work steps next to your assembly line, making it just as long as the assembly line (plus maybe some space for getting parts on and off). This is (in theory!) the line balancing for an continuously moving assembly line. You can assign a slot of space on the assembly line that fits exactly the slot of time needed for each work step… except that you still need to distribute the workers and machines, which again forces you to do a proper line balancing. Hence, the image below is usually unobtainable in its pure form, but there are some situations where you can use this situation to your advantage to save space. More on this in the subsequent post in this series.

Continuously Moving Lines Not Bound by Station Size

The main difference with a continuously moving assembly line is that the length of a workstation on an continuously moving line is not bound by the takt. It does not have to be the same length at every station, but the length of the station can vary. This possibility to divide the continuously moving assembly line into slices gives us a lot of options. But be aware that this applies only to the work content assigned to a distance on the line. The workers can NOT be cut into slices of the desired size; either you have a worker for an area of the line or you don’t. This takes away a lot of the advantage of the continuously moving assembly line. However, in some cases a bit of advantage remains.

Obviously, you would group work content (including losses) to fill one customer takt worth of work, just as you would do with a pulsed line. The difference between a takt (including losses) and the cycle time (excluding losses) is the OEE, and your line has to match the customer takt in average, not only in an ideal case. (More on this in my next post.) For tasks that exceed your customer takt, you have to assign multiple workers, and ideally it is also a multiple of the takt time. Whenever the work assigned to a worker does not match the takt time, then you run into inefficiencies.

- If the worker on average is faster than the takt, then the worker has to wait for the next part.

- If the worker on average cannot do the work within the takt, then your line will slow down and stop, and all other workers will have to wait more.

In sum, the more you miss the (multiple of the) takt time, the longer your workers will wait. So far this is just as it is in a pulsed line. However, the continuously moving line offers a few advantages. You can use fractions of the takt (i.e., different lengths of the assembly line) in two cases:

- Buffer against fluctuations. Normally, buffers are always a whole integer of parts. In a continuously moving assembly line, however, you can also have a buffer of less than one full takt (i.e., less than one part). The worker gets some extra space on the line in case it takes longer. Importantly, however, the worker on average still has to make the takt time, otherwise the line will slow down. When covering fluctuations with line length, it merely means that the worker can take a bit more time for one part if he makes the next part faster.

- Worker independent time content. In some (admittedly uncommon) cases, you have a part or product that needs to spend some time without any worker or any machine. Examples for this are a part that comes from an oven and has to cool down, or a glue that needs to harden, or a cement that needs to cure, etc. The part needs time to cool/harden/cure/etc. , but it does not need a worker or an automatic machine. In this case, the part gets the right space on the assembly line that gives the needed time to cool/harden/cure/etc., regardless if this time is a multiple of the takt time.

But I will discuss this in much more detail in my subsequent posts of this series. My next post will look at the math of the relation between speed (takt), length, and work content for continuously moving assembly lines, before subsequent posts digs deeper on how to assign times to workers and line segments, including the special cases of buffer against fluctuations and worker independent time content. But until then, go out, get your lines set up right, and organize your industry!

PS: This series of blog post was inspired by Sobha Modular.

Very interesting!