In my last post I went into detail on the concept and philosophy of flow. This post goes deeper and looks at one-piece flow. If you are working in manufacturing, you surely must have heard the term one-piece flow. However, despite it being ubiquitous, I find that this is still often not very well understood. I also sometimes have the feeling that it is also used as a buzzword merely to impress others. Well, let’s have a look.

In my last post I went into detail on the concept and philosophy of flow. This post goes deeper and looks at one-piece flow. If you are working in manufacturing, you surely must have heard the term one-piece flow. However, despite it being ubiquitous, I find that this is still often not very well understood. I also sometimes have the feeling that it is also used as a buzzword merely to impress others. Well, let’s have a look.

A Quick Recap on Flow

Quick Recap: Flow is the idea that parts are moving or being processed, opposite of them being idle. The idea behind it is to reduce inventory and to reduce lead time. In reality, however, a much better measure for this would be the percentage of the value-added time, since the flow itself (i.e., the transport) is also a waste and should be reduced if possible. You will also never achieve 100% flow, even though this is the true north.

Quick Recap: Flow is the idea that parts are moving or being processed, opposite of them being idle. The idea behind it is to reduce inventory and to reduce lead time. In reality, however, a much better measure for this would be the percentage of the value-added time, since the flow itself (i.e., the transport) is also a waste and should be reduced if possible. You will also never achieve 100% flow, even though this is the true north.

What is One-Piece Flow?

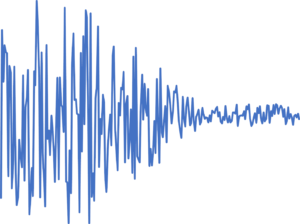

One-piece flow moves each product to the next stage as soon as it is completed at the previous stage in the value stream. The next stage should be ready to accept the part immediately. There is no accumulation of larger batches for moving material. The basic idea of one-piece flow is that you do not wait until you have a pallet/box/batch of parts before moving them to the next process, but that you move smaller quantities more frequently. Ideally, the transport quantity is one. The benefit of one-piece flow is also a reduction of fluctuations and hence a reduction of work in progress inventory. You don’t get a big box and then nothing, but you get the parts one by one, ideally just in time when you need them.

This helps to reduce transit time of the material through the value stream, and reduces the lead time. The system can react faster, and information can flow quicker. For example, if a subsequent station notices a systematic defect, a faster transit time means that there is less material in between that has to be reworked or scrapped.

What It Is Not: Lot Size One

I often find that one-piece flow is confused with a lot size of one. A smaller lot size is indeed beneficial to manufacturing, and the true north lot size is one. Different from many other true-north goals, a lot size of one is indeed achievable. Through smaller lot sizes you can also reduce your inventory fluctuations, and hence your buffer inventories.

However, in terms of one-piece flow, you can achieve it even with larger lot sizes. Even larger batches of material can be flowing well, provided that you don’t move them as batches but as individual items. In one-piece flow, you can move a larger batch one by one through your value stream, instead of a large pallet/box/batch. Similarly, you have a lot size of one but still no one-piece flow if you move the individual items in larger batches.

Hence, lot size one and one-piece flow can exist independent from each other. On the other hand, it is often easier to do both and there is a mutual benefit. Having smaller lot sizes helps with one-piece flow, and having one-piece flow may be better for smaller lot sizes. But both are also valid goals on its own. Again, one-piece flow refers not to the lot size, but to the transport quantity.

What It Is Not: Buffer Inventory Reduction

Another common confusion is to consider one-piece flow a reduction of the buffer inventories. These, too, are related, but not identical. Buffer inventory is used to decouple fluctuations. Less inventory has many benefits – provided you can get your fluctuations under control. Like the lot size one, one-piece flow and small buffers also create a mutual benefit and are both worthwhile. Besides, it is quite possible to have zero buffer inventory between well-balanced processes.

There are even more misunderstandings on one-piece flow. The German Wikipedia claims it is group work on a moving conveyor, which is hogwash, besides also claiming a lot size of one. Other books go heavily in the direction of cellular manufacturing (which, admittedly, often use one-piece flow). Overall, there seems to be still much confusion. Or, maybe I am confused? If so, let me know.

There are even more misunderstandings on one-piece flow. The German Wikipedia claims it is group work on a moving conveyor, which is hogwash, besides also claiming a lot size of one. Other books go heavily in the direction of cellular manufacturing (which, admittedly, often use one-piece flow). Overall, there seems to be still much confusion. Or, maybe I am confused? If so, let me know.

The Benefits of One-Piece Flow

One benefit of one-piece flow is the reduction of fluctuations by having larger quantities stop and go through the value stream. This in turn allows a reduction of (buffer) inventory, which will generate a whole lot of other benefits, from less tied-up cost to faster lead times and information flows. Especially the faster reaction to quality problems is often quite important here.

One benefit of one-piece flow is the reduction of fluctuations by having larger quantities stop and go through the value stream. This in turn allows a reduction of (buffer) inventory, which will generate a whole lot of other benefits, from less tied-up cost to faster lead times and information flows. Especially the faster reaction to quality problems is often quite important here.

It also makes it easier to maintain a FIFO (First in first out) sequence. This also has many benefits, like reducing lead time fluctuations, which makes planning the delivery dates much easier. It also helps with the tracing of quality problems.

The Goal of One-Piece Flow

The goal of one-piece flow is to have the items move one by one through the value stream as soon as they are ready for the next stage. Hence, the true north is a transport size of one item. Within a factory this is often possible. Most assembly lines, or even most manufacturing lines, move an item to the next station as soon as it is possible with a transport quantity of one.

It is often more difficult outside of factories. If you are shipping items between suppliers, factories, and customers, it may often not make sense to send out a truck for a single item. Instead, you send out a truckload.

But even if you cannot reach a true one-piece flow, you still may be able to move in that direction. Instead of one large truck, can you send two smaller ones? Instead of a truck full of one item, could you send smaller quantities of different items? Could an external milk run pick up smaller quantities more frequently from different sources?

Overall, I see one-piece flow as a good visualization of the goal of flow, but to me the concept of flow itself is a bit misleading. Transport is, after all, waste. While not completely avoidable, transport should be reduced to the minimum. But there is definitely benefit in reducing the quantity of transports and increasing the frequency. If I would pick an actual KPI, the percentage value add is more relevant to me. It is easy to have tons of material moving around the world in complete opposition to the visions of lean manufacturing.

I hope this post was made you think more about flow. Now, go out, don’t only think about flow but get your material flowing, and organize your industry!

Really good Christopher. For the first time I’m understanding this concept with clarity.

Thanks for simplyfing the concerpt.

Good to know! Definitely will use this knowledge.

Great article. Thank you.

I think the the real benefit is that moving to one-piece flow exposes all the problems in the system that make it hard to make/move one piece at a time. I think that is the beauty of it. It requires excellent quality and no waste.

Great post!

To this day, concepts like one-piece-flow, lot size 1, buffer inventory, and batching have way too much dogma around them to the point where it overrides common sense in case of obvious conflicts.

This gets tricky when you have a mix of processes that are discrete from each other, work on batch inputs e.g. a dishwasher, and processes that are complicated to stop and restart.

Hands down, the absolute #1 benefit of one-piece flow is the reduction of half-finished parts stacked around i.e. WIP and all of the associated wastes that go with it e.g. things have to be moved around when there’s a switch.

Another case would be a subassembly line made up of however many processes that produces subassemblies that are used by the main line. It’s a completely sensible thing to do to have the output subassemblies to be placed onto a pallet until it’s full and a forklift grabs it for delivery to the main line. Sure, it would be awesome to relocate the entire line so that the finished sub-assys are fed straight to the receiving line without extra transportation. Whether that’s even practical or worth the time and expense is a different story.

Batching is another concept that often conflicts with the dogma. It’s a silly example, but how about cooking bulk foods such as rice at home. Do the purists insist on preparing and eating rice one grain at a time? With enough money and inclination, it’s entirely possible to build a machine that will prepare rice on a grain-by-grain basis. But should we? Or is setting the batch size to a reasonable amount e.g. prepare a dinner’s worth at a time vs preparing the entire 50lbs bag more than good enough?

It would be cool to see a post on how to choose lot sizes and the nuances of where buffer inventory becomes overproduction, and vice versa. It’s very common urge to reduce extra inventory to nothing in the beginning, and some overproduction gets traded in favor of daily firefighting.

Many thanks, Andrey. Indeed, it is often used as a buzzword, or as a strict rule, whereas it is more of a true north that may in its ultimate form not always make sense at the current system, but should give you the direction of improvement.

Same with lot sizes as you mentioned. I have an online calculator for buffer sizes and wanted to write an article about lot sizes for quite some time now. But no promises on when I get around to write it 🙂

This was a great post to read because it really does simplify a lot of concepts regarding flow. I have previously heard words like one-piece flow, lot size one, and buffer inventory but never fully understood them or the role they all play together. It seems like one-piece flow has many benefits if done properly, especially in a manufacturing setting. I am curious to know what types of companies use this strategy and how it works out for them compared to a large pallet/box/batch strategy.